Stay ahead of the game with free sample reports from top publishers across the globe!

Reports Coverage

Sheet Metal Flexible Manufacturing Systems Market Key Insights

Sheet Metal Flexible Manufacturing Systems Market Analysis by Regions

Sheet Metal Flexible Manufacturing Systems Market Analysis by Segments

Sheet Metal Flexible Manufacturing Systems Market Size (current and future)

Sheet Metal Flexible Manufacturing Systems Market Competitive Benchmarking

a year ago

Global Sheet Metal Flexible Manufacturing Systems Market Research Report 2023

This report aims to provide a comprehensive presentation of the global market for Sheet Metal Flexible Manufacturing Systems, with both quantitative and qualitative analysis, to help readers develop business/growth strategies, assess the market competitive situation, analyze their position in the current marketplace, and make informed business decisions regarding Sheet Metal Flexible Manufactur...

Sheet Metal Flexible Manufacturing Systems Market

"Sheet Metal Flexible Manufacturing Systems Market" refers to flexible manufacturing systems specifically designed for sheet metal fabrication processes. Flexible Manufacturing Systems (FMS) are automated manufacturing systems that integrate various machines, robots, and computer-controlled processes to efficiently produce a wide range of parts or products with minimal human intervention. The Sheet Metal Flexible Manufacturing Systems Market involves the use of these automated systems in the sheet metal industry to streamline and optimize the production of sheet metal components. These systems are capable of handling various tasks, such as cutting, bending, punching, welding, and assembling sheet metal parts, offering manufacturers greater flexibility, speed, and cost-efficiency in their production processes.

Here are some of the Current Market Trends in this market:

Advanced Automation: The adoption of advanced robotics, artificial intelligence, and machine learning in manufacturing processes continues to grow, leading to increased efficiency and productivity.

Internet of Things (IoT): IoT enables connected machines and devices, facilitating real-time data monitoring, predictive maintenance, and enhanced process optimization.

Additive Manufacturing (3D Printing): The use of 3D Printing in manufacturing has expanded, allowing for rapid prototyping, customized production, and reduced material waste.

Sustainable Manufacturing: There is a growing focus on sustainable and eco-friendly manufacturing practices driven by consumer demand and environmental concerns.

Here are some of the Growth and factors in this market:

Increasing Demand: Global population growth and rising middle-class consumer demands are driving the need for increased production across various industries.

Cost and Resource Optimisation: Manufacturers seek ways to optimize costs and utilize resources more efficiently to remain competitive.

Globalization and Supply Chain Complexity: Manufacturers are expanding their operations globally, necessitating more sophisticated supply chain management.

Shorter Product Life Cycles: The need to bring products to market faster drives the adoption of agile and flexible manufacturing systems.

Here are some of the Risks and Challenges in this market:

Supply Chain Disruptions: Natural disasters, geopolitical tensions, or pandemics can disrupt the supply chain, affecting production and distribution.

Cybersecurity Threats: As factories become more connected and digitalized, the risk of cyberattacks on critical infrastructure increases.

Economic Uncertainty: Global economic fluctuations and geopolitical events can impact demand, supply, and overall market stability.

Technological Obsolescence: Rapid advancements in technology may lead to equipment or processes becoming outdated quickly.

Here are some of the Opportunities in this market:

Innovation and Product Development: Investment in R&D can lead to the development of new and improved products, capturing market share.

Market Expansion: Entering new geographic markets or diversifying product portfolios can open up new growth opportunities.

Sustainable Practises: Embracing eco-friendly manufacturing practices can attract environmentally conscious consumers.

Reshoring and Localization: Companies might consider reshoring manufacturing operations to reduce supply chain risks and improve responsiveness.

Key players in the Sheet Metal Flexible Manufacturing Systems Market include Murata Machinery, Ltd., LVD Group, Prima Power, Mazak Corporation, Salvagnini Group, Bystronic AG, Amada Holdings Co., Ltd., Trumpf Group, ETC.

Frequently Asked Questions

How to Compare Table of Contents of Sheet Metal Flexible Manufacturing Systems Market?

How to compare reports on Sheet Metal Flexible Manufacturing Systems Market?

Can i compare reports on Sheet Metal Flexible Manufacturing Systems Market?

Continue Reading

Three Works by Willem De Kooning Are Set to Auction This Fall

This fall, Sotheby's will auction three artworks by Willem De Kooning. Read ahead to find out more about De Kooning as an artist and how his three works have come up for auction.

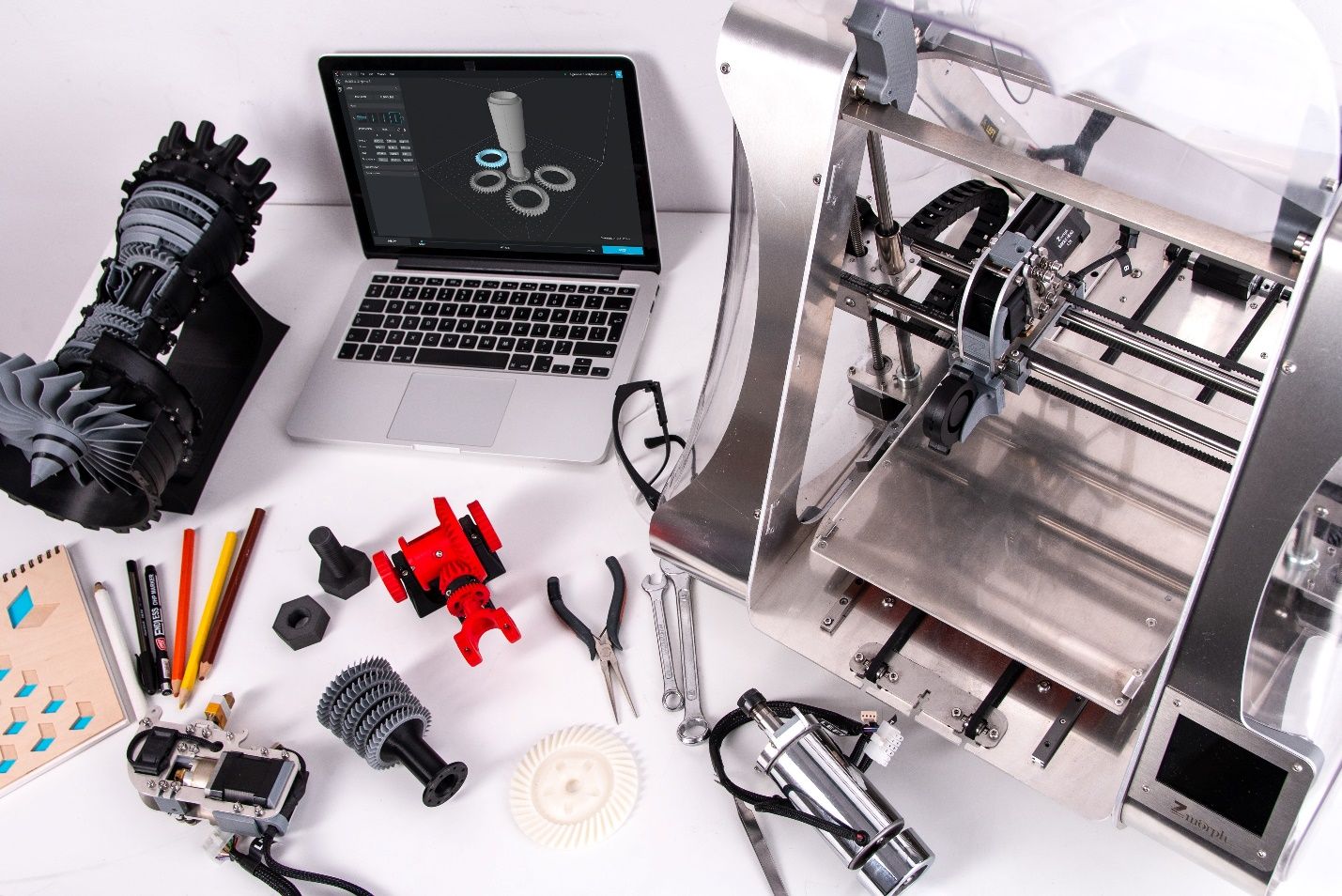

Six Leading 3D Printer Manufacturers

3D printers are the next big thing in manufacturing procedures. Technological advancements ensure this invention is here to stay for good. They’ve made production easier, quicker, and, most importantly: more accurate. Precision helps reduce wastage, especially prototyping, enabling users to satisfy their clients the best.

Five Biggest Scented-Candle Manufacturers Worldwide

Scented candles are soothing, rejuvenating, and relaxing creations commonly used for their pleasant and aromatic after-scent.

Recent Press Releases

Douglas Insights Adds Fall Management Market Research Reports to Its Comparison Engine

Douglas Insights has further expanded its comparison engine with Fall Management Market research reports, allowing market researchers, analysts, industry exp...

Douglas Insights Includes Hip Replacement Implants Market to Its Comparison Engine

Douglas Insights has introduced the Hip Replacement Implants Market research report in its comparison, allowing key players in the industry, professionals, a...

Douglas Insights Adds Blockchain Technology in Healthcare Market Research Reports to It...

Douglas Insights is pleased to add blockchain technology to healthcare market research reports in its revolutionary comparison engine, helping market analyst...